Concept Development

We take the time to truly listen to the needs of our clients, then develop efficient machines to meet those needs.

System Level Analysis

- Requirements Review and Creation

- DFM, Poke-Yoke, Serviceability

- Tolerance Stack-up and Constraint Analysis

- Assembly Aids and Tooling Requirements

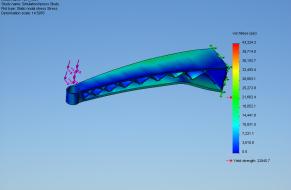

Analysis of Machine Elements

- FEA, Stress, Strain, and Deflection

- Life and Fatigue Analysis

- Manufacturability, finding the proper fabrication techniques

- Vibration and Modal Analysis

Detail Design

- SolidWorks CAD models

- Drawings complete with dimensioning, GD&T, and finishing

- Bill of Materials and costed BOMs

- Assembly Drawing and Assembly Instructions

Technical and Non-Technical Reports

We have the ability to produce technical reports including calculations and raw data for the more technical clients. We also have the ability to blend CAD models, technical data, and concepts into a report that works well for technical and non-technical personnel. This can be a very powerful tool for management and executive meetings.

Procurement and Assembly of Prototypes

The founder of True North Automation has a long history of working with suppliers, from machine shops to motion control companies, and use this experience to procure and build the first prototypes of your machines.